Did you see our blog last week ‘Digitization of production‘? We talked in a general way about the solutions provided by new technological tools. In this blog, we’ll talk more about one of those solutions: digital production management.

Why does your factory need a digital production management system?

If you are responsible for the company’s production, you should ask yourself these questions:

- What is happening now in your factory?

- Do you know the performance (OEE) of your production centers?

- Do you control the LeadTime of your production process?

If the answer you have to these questions is NO. YOU NEED THIS DIGITAL PRODUCTION MANAGEMENT SYSTEM!

Among the benefits of using this system are:

- Increases efficiency.

- Streamlines the supply chain.

- Demand-driven production.

- Facilitates plant decision making with visual tools to drive

- visual tools to drive operational improvement.

- Communicates the production process with the business

Objectives of a digital production management system

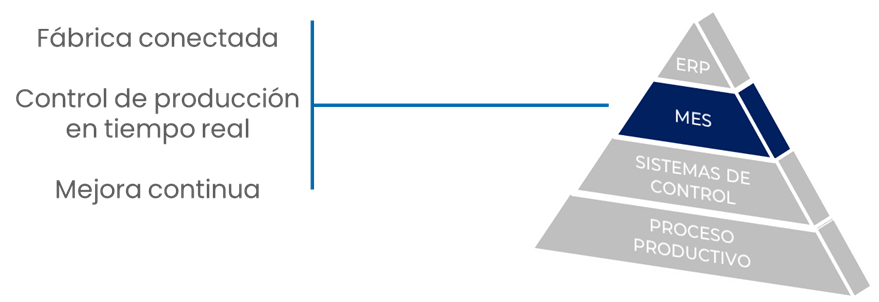

Connected factory

Automated and centralized plant production data capture; controlling quality, traceability and information generated.

Control de producción en tiempo real

Real-time equipment analysis (OEE); for total production control. Supply chain optimization

- Planning.

- Raw material stock.

- Lead time.

Mejora continua de los procesos productivos

Continuous manufacturing improvement. Based on the analysis of information captured in real time; and the knowledge generated from this information.

Benefits for each level of decision making

Production operator

1. Information necessary for the execution of the functions.

2. Real-time production information.

3. Knowledge of the incidences associated with the job to optimize decision making.

Production Manager

- Plan, manage, control and monitor in real time:

- Production processes.

- Orders addressed to operators

2. Access to information:

- Condition of machines.

- Reasons for lack of efficiency.

- Status in the progress of operations.

- Performance indicators.

3. Analysis and monitoring of downtime reasons:

- Maintenance.

- Operator rest.

- Machine failure.

Business management

1. Visibility of production information; for optimal business decision making.

2. Providing valuable information on the relationship between the cost of production and its impact on quality.

3. Optimization of adaptability in the creation of new processes for the development of new products.

The tool that we recommend

CAPTOR is the MES system (Manufacturing Execution System).

Designed to provide technological intelligence in the decision making process in the plant.

The organizational deployment of the tool allows to increase efficiency, streamline the supply chain, flexibly adjust to demand needs, synchronize manufacturing processes and have real-time plant status.

Therefore, its knowledge generation tools enable accelerated operational improvements (industrial metrics) in the plant, making them visible in optimized business indicators.

Funtions:

- Calculate local and plant OEE.

- Real-time reaction to production events.

- Traceability and synchronization of plant processes.

- Supply chain optimization.

- Synthesize process information (API).

Did you like this article?

Receive new articles in your email weekly.

Technology and industry trends, and Industry 4.0.

Subscribe to our newsletter

If you would like more information or have questions or ideas you would like to share with Innova IT: send us a message to comercial@innovait.cat or fill out the form below and we will get back to you as soon as possible.

For something more specific and concrete, make an appointment and visit us at our premises.