We are getting closer and closer to Expoquimia, and this sector is starting to stand out among solutions and success stories. Today we bring a project developed through a MES Solution for the chemical industry, which achieved the optimisation of productivity and brought technological intelligence to decision-making in the plant, achieving an improvement in production.

THE COMPANY.

This project was developed for a company that manufactures chemical specialities and is made up of four large differentiated areas: Performance Materials, Food Processing Aids, Additives and Adhesives. Through them, it provides a worldwide service and coverage to a wide range of customers in the industrial sector. Many of its products are nowadays leaders in the international market.

COMPANY NEEDS

As such a large company, it had general challenges and needs to help optimise productivity:

- Real-time production analysis.

- Reduction of production costs.

- Streamline decision making by workstation.

- Shift production control.

- Advanced production analytics

SOLUTION

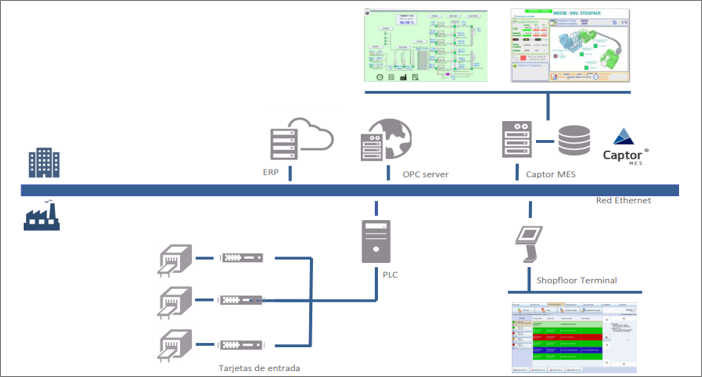

After carrying out a diagnosis and identifying the needs, a MES solution was recommended.

MES is a system that achieves the development of solutions for the management of intelligent production. Therefore, it can adapt to the needs of any type of company; this is how INNOVA IT proposed to develop this project to achieve the optimisation of productivity by providing technological intelligence to decision-making in the plant and thus achieve an improvement in production.

The MES product we used was:

PROJECT DEVELOPMENT

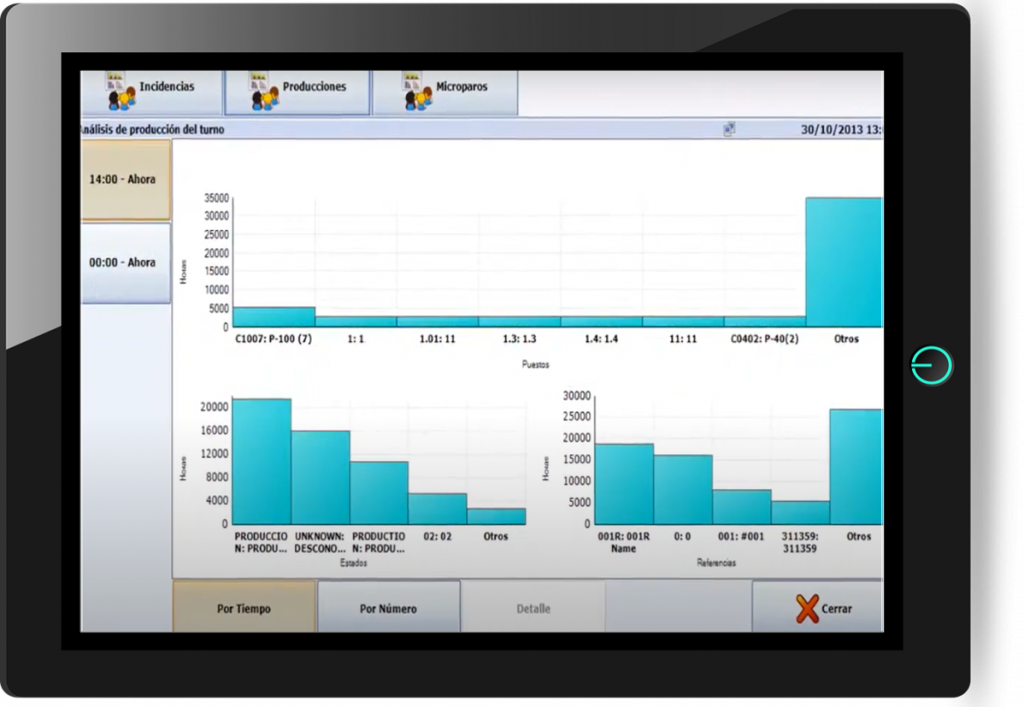

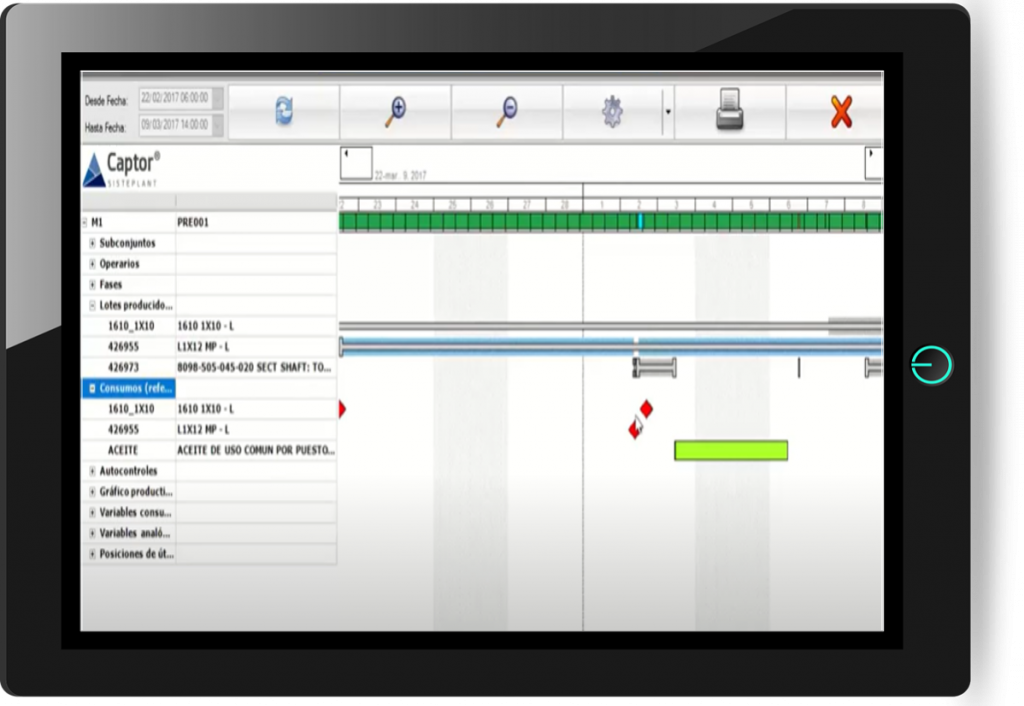

- OEE and LTA (Lost Time Analyses) Analysis

- Design and implementation of real-time control Dashboards:

- Analysis of production ratios.

- Supervision management by area.

- Operator management by turn

- Tracking of production by turn.

- Analysis of historical and evolutionary OEE and LTA.

- Master data integration.

RESULTS

- Improvement of OEE (productivity).

- Reduction of deviations on planning.

- Reduction of production stoppages.

- Faster delivery times.

- Less work in progress (WIP).

- Reduced inventories.

A project with highly favourable results for the company.

The application of an MES Solution for the chemical industry is very useful, but within companies in this sector there may also be many other needs that we are sure we can solve.

See more information about our solutions at:

- Automated maintenance: CMMS

- Flow planning and control: Polca Planner

- IoT Solutions: Industrial IoT

- Machine Learning: Analytics & machine learning

- All the digitisation solutions we offer: Solutions

Did you like this article?

Receive new articles about technology and industry trends, and Industry 4.0 in your email weekly.

Subscribe to our newsletter

If you would like more information or have questions or ideas you would like to share with Innova IT: send us a message to comercial@innovait.cat or fill out the form below and we will get back to you as soon as possible.

For something more specific and concrete, make an appointment and visit us at our premises.

3 things to know before EXPOQUIMIA - Innova IT

[…] From Innova IT we recommend you to see our last Blog, where we talk in detail aboutan MES solution project for a company in the chemical sector. […]

Chemical sector in Catalonia - Innova IT

[…] fact, at Innova IT we recently developed an MES solution for a company in the chemical sector that has yielded very good […]