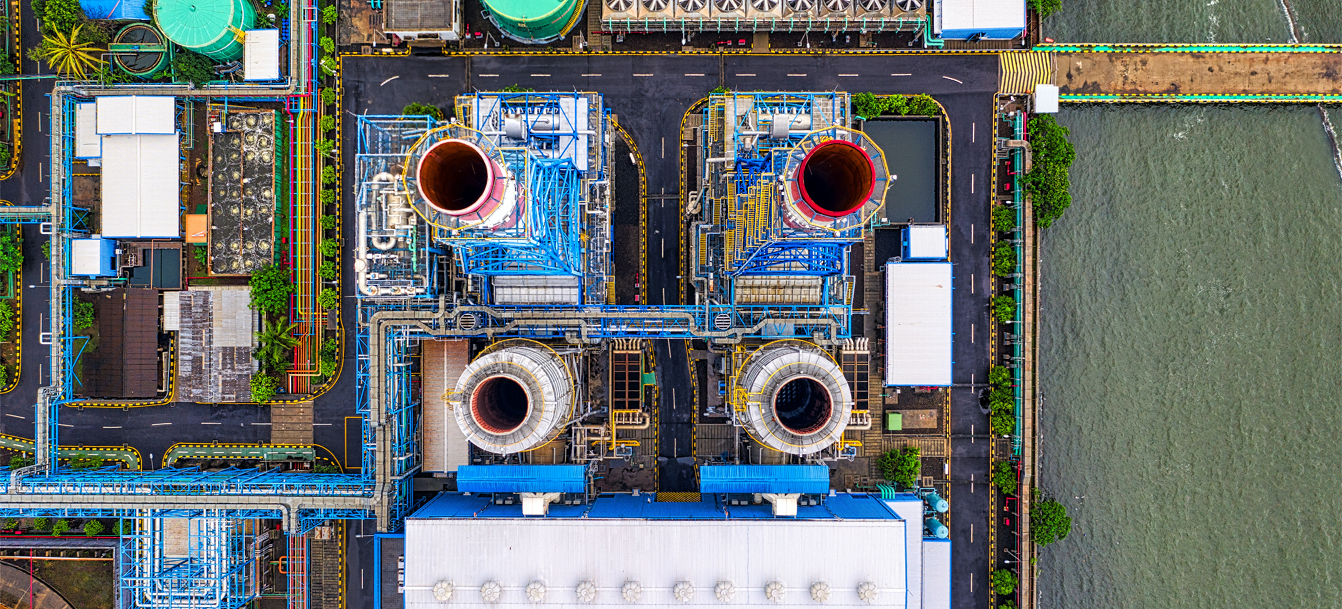

This solution was applied to a water treatment plant in which waste, floating grease and oil, sand and all coarse elements that may be contained in the water can be removed; decantable materials, both organic and inorganic, can be removed; in general asset management to remove biodegradable organic matter dissolved in water.

More applicable solutions for companies in industrial sectors

NEEDS

Avoid downtime of the plant’s motors and pumps, thus causing.

- Discharge of untreated water into the environment.

- Manual system for data collection and analysis of the critical variables of the equipment, as a result:

- High response time in corrective and preventive actions.

- Mechanical deterioration of the equipment

- Decrease in the useful life of the equipment.

- Decrease in equipment performance

- High operational cost

- Poor traceability of maintenance tasks by the owner.

DEVELOPMENT

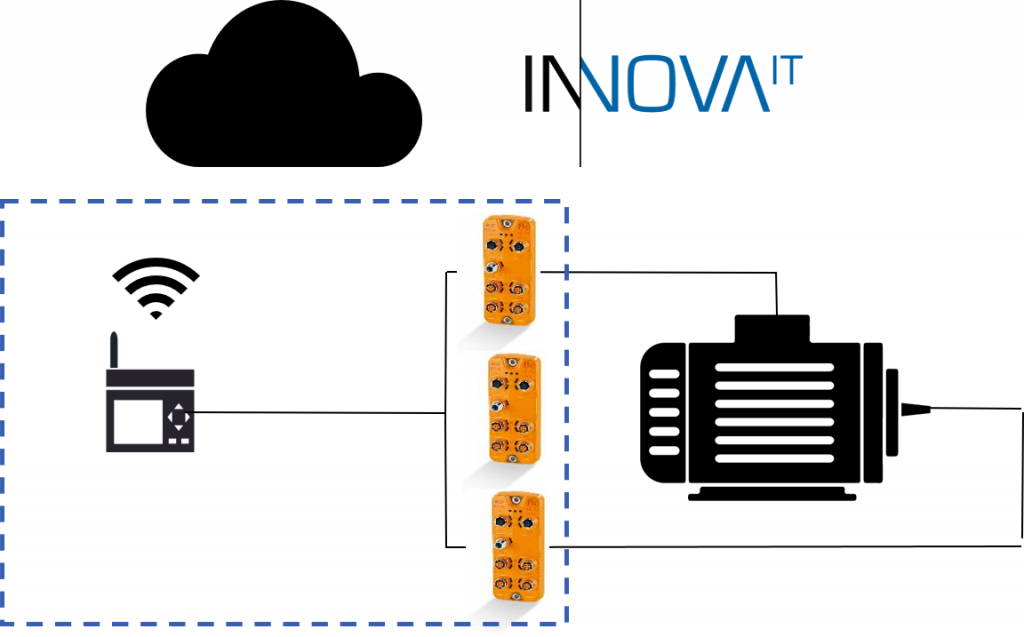

Monitoring and remote control system for the detection of anomalies in pumps and motors:

Vibration | Bearings | Cavitation | Misalignment | Misalignment | Unbalances

- Vibration diagnostics

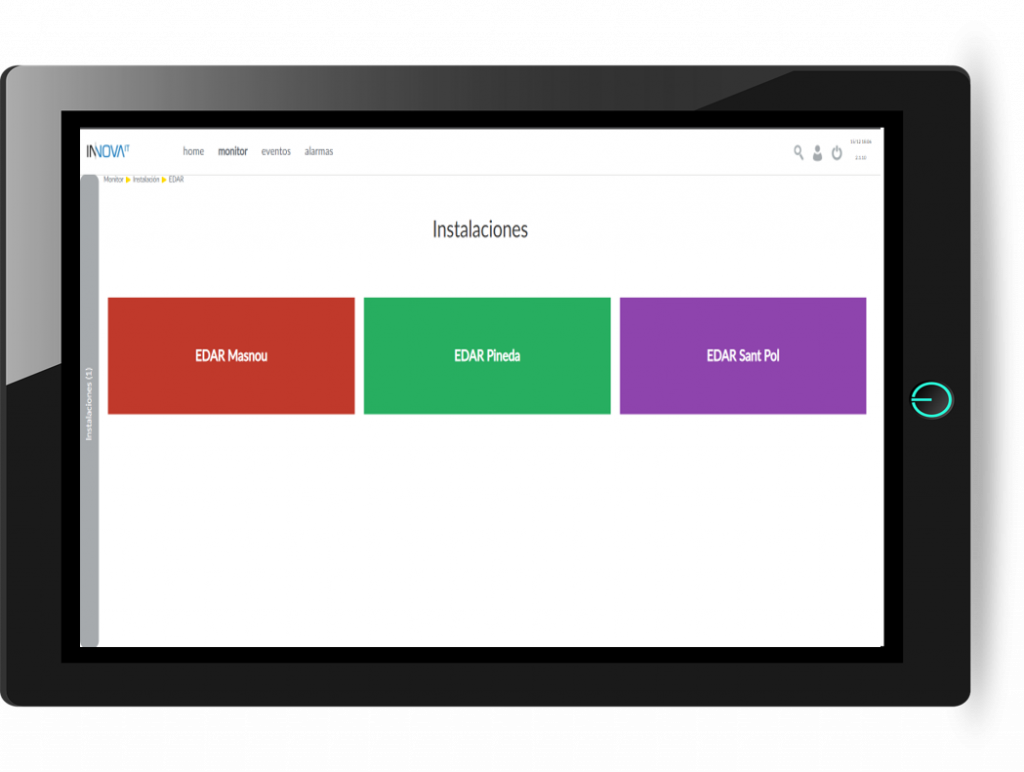

- Remote management and configuration of intelligent sensors

- Automatic detection of equipment anomalies

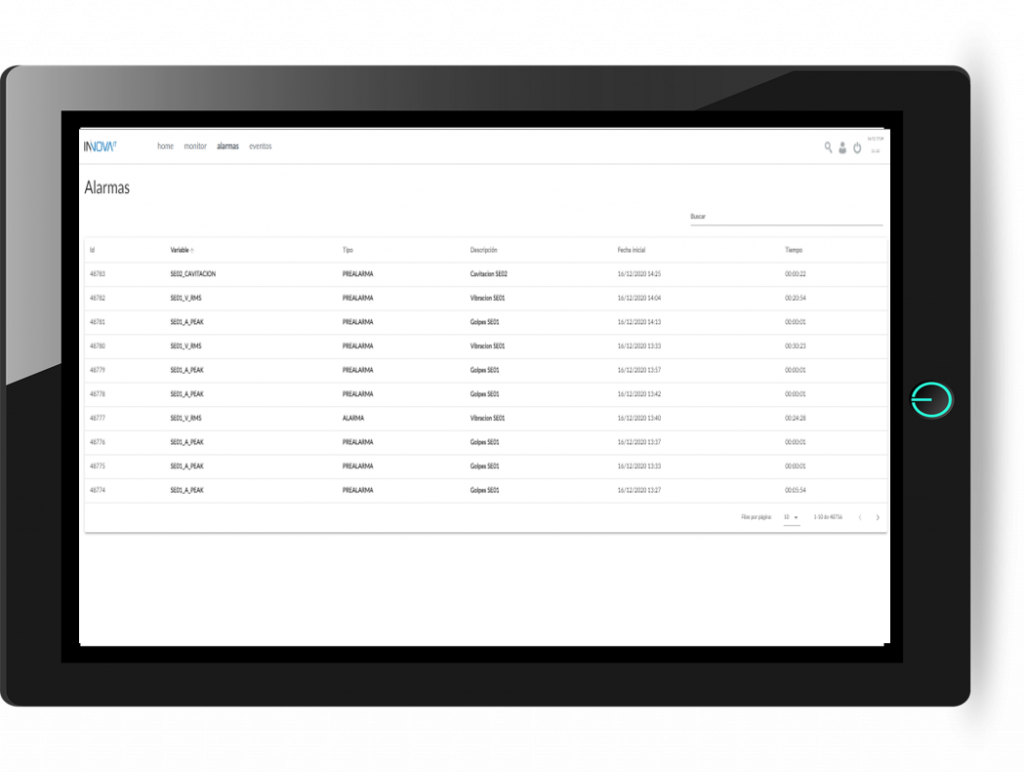

- Incident management of preventive alarms

- Easy installation and configuration system (Plug&play)

- Measurement history management and analysis

- Integration with management systems now CMMS, ERP, MES etc.

RESULTS

- Reduced downtime

- Economic savings while improving production

- Improved environmental impact

- Improved asset management i working conditions

Did you like this article?

Receive new articles about technology and industry trends, and Industry 4.0 in your email weekly.

Subscribe to our newsletter

If you would like more information or have questions or ideas you would like to share with Innova IT: send us a message to comercial@innovait.cat or fill out the form below and we will get back to you as soon as possible.

For something more specific and concrete, make an appointment and visit us at our premises.